Tool Room & Manufacturing Design at Marcus Hi-Tech Engineering

The Tool Room at Marcus Hi-Tech Engineering is the core of our precision manufacturing capabilities. As an integral part of our in-house operations, it ensures complete control over die design, manufacturing, and maintenance, guaranteeing the highest quality and efficiency for every project.

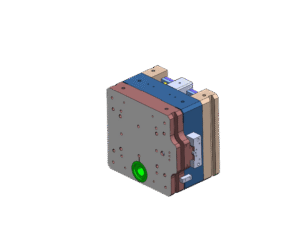

Our dedicated team of engineers and toolmakers leverages advanced CAD/CAM technologies to transform complex designs into robust, high-performance tooling, critical for die casting, forging, and plastic injection molding.

Integrated Tool Design & Simulation

Solutions & Benefits

In-House Tool Manufacturing

- Precision Machining: Equipped with high-precision CNC machines, EDM, and grinding capabilities for intricate tool component fabrication.

- Material Expertise: Selection and processing of high-grade tool steels for maximum durability and lifespan.

- Rapid Prototyping: Capabilities to produce prototypes quickly, facilitating design validation and accelerating time-to-market.

Tool Maintenance & Lifecycle Support

- Preventive Maintenance: Regular inspection and maintenance programs to extend tool life and prevent unexpected downtime in manufacturing.

- Repair & Refurbishment: Expert repair services to restore tools to optimal condition, ensuring continuous production.

- Engineering Changes: Agile modification capabilities to adapt tooling for design updates or process improvements.

Validation & Trials

- Tool Trials: Rigorous initial trials conducted in-house to validate tool performance, part quality, and process stability before full-scale manufacturing production.

- FAIR (First Article Inspection Reports): Comprehensive reports generated to confirm that initial production parts meet all specifications.

- PPAP:

Frequently Asked Questions

What role does Marcus's in-house Tool Room play in the manufacturing process?

Our in-house Tool Room is fundamental to our precision manufacturing. It provides complete control over the design, fabrication, and maintenance of all tooling (dies, molds, fixtures). This ensures optimal tool performance, consistent part quality, reduced lead times, and the flexibility to implement design changes quickly for our die casting, forging, and plastic injection molding operations.

How does Marcus ensure the quality and efficiency of its tooling?

We ensure tooling quality and efficiency through several key practices:

• Advanced CAD/CAM integration for precise design.

• Design for Manufacturability (DFM) principles to optimize tool performance.

• Process simulation to predict and prevent potential issues.

• High-precision CNC machining for fabrication.

• Rigorous T0 & T1 trials to validate tool performance before mass production.

• Comprehensive preventive maintenance programs to extend tool life.

• Advanced CAD/CAM integration for precise design.

• Design for Manufacturability (DFM) principles to optimize tool performance.

• Process simulation to predict and prevent potential issues.

• High-precision CNC machining for fabrication.

• Rigorous T0 & T1 trials to validate tool performance before mass production.

• Comprehensive preventive maintenance programs to extend tool life.

Can Marcus's Tool Room assist with new product development (NPD) and prototyping?

Absolutely. Our Tool Room is a critical asset for New Product Development (NPD). We actively engage in DFM to optimize designs for efficient manufacturing. We also have capabilities for rapid prototyping and can quickly produce initial samples and conduct FAIR (First Article Inspection Reports) to validate designs and tooling, significantly accelerating your product's time-to-market.

What materials are typically used for tooling at Marcus?

We select high-grade tool steels and other specialized materials based on the specific application and expected production volumes. Our material selection ensures maximum durability, heat resistance, and longevity for the tooling, which is crucial for maintaining consistent quality throughout the manufacturing lifecycle of your components.

Certificates