Partnered Facilities – Surface Treatment

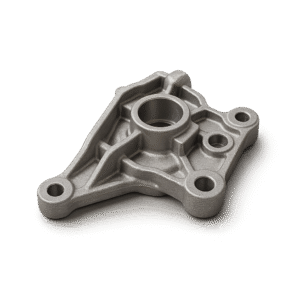

At Marcus Hi-Tech Engineering, our precision casting and machining capabilities are enhanced through collaboration with world-class surface treatment partner facilities in addition to the in-house surface treatment facility.

Our partners provide a complete range of protective and decorative finishing solutions — including powder coating, anodizing, plating, wet painting, and e-coat — to deliver high-performance components with superior durability, corrosion resistance, and aesthetics.

Solutions & Benefits

Powder Coating

- High-quality, durable finish with resistance to impact, abrasion, and corrosion

- Available in a wide range of colors & textures

- Eco-friendly alternative to conventional wet paints

Anodising

- Enhanced corrosion resistance for aluminum components

- Increased surface hardness and resistance to wear

- Options for decorative finishes in different colors

Plating (Electroplating & Electroless)

- Nickel Plating (Ni): Superior wear and corrosion resistance

- Chrome Plating: Decorative, durable finish with high resistance to tarnish

- Other coatings: Silver, zinc, and specialty plating available

Painting & Coating

- Wet Painting & Spray Painting – versatile for automotive, appliances, and industrial components

- E-Coat (Electrophoretic Coating) – uniform coating with excellent adhesion and corrosion resistance

- Custom finishes to meet OEM specifications

Specialized Treatments

- Shot Blasting & Bead Blasting – excellent adhesion preparation & final surface refinement

- Vibro Polishing – for smooth finishing on intricate parts

- Resin Impregnation – sealing porous castings to improve leak resistance

- Chromation/Conversion Coating – for corrosion protection and paint adhesion

Frequently Asked Questions

What types of surface treatments does Marcus offer through its partners?

Through our specialized partner network, Marcus provides a comprehensive range of surface treatments. These include powder coating, wet painting, E-coat, anodising, chrome plating, nickel plating, shot/bead blasting, vibro polishing, resin impregnation, and chromation. These processes enhance component durability, corrosion resistance, and aesthetic appeal.

How does Marcus ensure the quality and consistency of surface treatments from partners?

We maintain stringent quality control over all partnered surface treatment facilities. Our partners adhere to IATF 16949:2016 and ISO 9001 standards, and we implement rigorous supplier audits, process validation, and final inspection protocols. This ensures that all treated components meet the exact specifications and quality benchmarks expected from Marcus.

Are the surface treatments offered compliant with environmental and industry standards?

Yes, all surface treatments provided through our partnered facilities are designed to comply with relevant environmental regulations such as RoHS and REACH, as well as specific industry standards, including those for the automotive and aerospace sectors. We prioritize sustainable and compliant finishing solutions.

Can Marcus recommend the best surface treatment for a specific application?

Absolutely. Our engineering team works closely with clients to understand the specific functional, environmental, and aesthetic requirements of their components. Based on the material, end-use, and desired properties, we can recommend and manage the optimal surface treatment solution from our extensive partner network.

Certificates