QA & QC Process at Marcus Hi-Tech Engineering

At Marcus Hi-Tech Engineering, quality is engineered into every stage of our precision manufacturing process, rather than inspected in at the end.

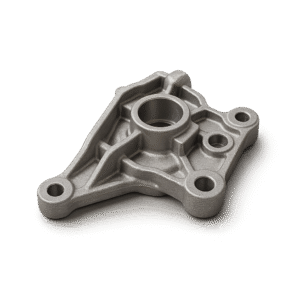

Our dedicated Quality Assurance (QA) and Quality Control (QC) systems ensure every die-cast, machined, and assembled component meets the highest international standards of precision, durability, and compliance.

We follow globally recognized automotive and aerospace quality systems, integrating advanced inspection technologies and rigorous process validations to deliver zero-defect, high-performance components.

Solutions & Benefits

Quality Assurance (QA) – Preventive Systems

Our QA approach ensures that defects are prevented before production begins by:

- Design for Manufacturability (DFM): Early-stage optimization of part designs

- APQP (Advanced Product Quality Planning): Customer-approved process planning framework

- PPAP (Production Part Approval Process): Demonstrating product & process validation before start of mass production

- Prototyping & Trials: T0/T1 runs to validate tool performance & manufacturability

- Process Control Plans: Documented preventive systems for every manufacturing stage

Quality Control (QC) – Inspection & Testing

Our QC process verifies precision & consistency during production:

- In-line Inspection – Continuous monitoring by operators and machines during runs.

- CMM (Coordinate Measuring Machine) – High-accuracy dimensional inspection

- Optical Emission Spectrometer (OES) – Material chemistry validation

- Leak Testing Systems – Ensuring pressure-tight castings

- Air Plug Gauges & Receiving Gauges – Real-time component verification

- FAIR (First Article Inspection Reports) – Certification of initial parts meeting all specifications

- Sampling Inspections – Random checks during production to maintain ongoing compliance

Continuous Improvement Programs

- Kaizen & Lean Initiatives: Enhancing efficiency and reducing waste

- CAPA (Corrective and Preventive Action): Systematic resolution of root-cause issues

- Training & Skill Development: Regular team training on QA/QC tools and methodologies.

- Customer Feedback Integration: Closed-loop system for continuous improvement and manufacturing excellence

Frequently Asked Questions

What types of die casting processes does Marcus Hi-Tech Engineering specialize in?

Marcus specializes in High-Pressure Die Casting (HPDC), Low-Pressure Die Casting (LPDC), and Gravity Die Casting (GDC). We work with a wide range of materials including aluminum, zinc, magnesium, and lead alloys, producing precision components for diverse industrial applications.

What are Marcus's key manufacturing capabilities beyond die casting?

Beyond our core die casting expertise, Marcus offers comprehensive manufacturing solutions. These include precision CNC machining (3/4/5 axis), a full suite of secondary operations (e.g., heat treatment, polishing, leak testing), various surface finishing options (e.g., powder coating, anodising, plating), and integrated assembly services. We also leverage partner facilities for forgings, extrusions, stamping, and plastic injection molding.

Where are Marcus Hi-Tech Engineering's manufacturing facilities located?

Marcus operates a global manufacturing footprint to serve our international clients. Our Die casting facility is in Coimbatore, India and partner networks are strategically located across India (including Pune, Bangalore, Chennai, Faridabad, etc.), Vietnam (Hanoi, Ho Chi Minh City), and China (Tianjin, Ningbo, Nanjing, etc.). This ensures efficient production and optimized supply chain logistics.

What quality certifications does Marcus hold for its manufacturing processes?

Quality is paramount at Marcus. We are proudly IATF 169949:2016 certified and ISO 9001 certified. Our robust Quality Management Systems (QMS) incorporate industry best practices such as DFM, APQP, PPAP, and FAIR, ensuring every component meets stringent global quality and performance standards.

Certificates